How Dynamic Scenario Simulation Builds Resilient Supply Chains in Uncertain Times

- Julien Brun

- Apr 15

- 8 min read

Updated: Apr 25

The global landscape is in constant flux. Between 2017 and 2022 levels of global disruption increased by 200%. In comparison, the Index rose by only 4% from 2011 to 2016. Geopolitical tensions simmer and erupt, economic policies shift overnight, climate events disrupt logistics, and unforeseen crises like pandemics, tariff wars, rewrite the rules of trade. For businesses reliant on intricate global supply chains, this volatility isn't just a challenge – it's the new reality to compose with. Reactive strategies, patching holes as they appear, are no longer sufficient. In this era of profound uncertainty, proactive planning and robust risk mitigation, powered by advanced technology, are paramount for survival and growth. Dynamic Scenario Simulation (DSS) emerges not just as an other fancy technology, but as a strategic imperative for navigating this complex environment.

Statista 2024, Global data

McKinsey Global Institute's "Risk, Resilience, and Rebalancing in Global Value Chains"

Deloitte's "Global Disruption Index"

BCG's "Global Trade Analysis"

The New Normal: Why Supply Chain Resilience is Non-Negotiable

We've moved beyond predictable cycles, according to McKinsey, major supply chain disruptions lasting over a month now occur every 3.7 years on average. Over a decade, these events can cost a company the equivalent of nearly half a year's profit. The confluence of the globalization longstanding globalization trend (connecting us more than ever) and rising geopolitical fragmentation (creating new barriers) presents a paradox. Add volatile energy prices, shifting trade alliances, sudden tariffs, sanctions, regional conflicts, and the ever-present threat of natural disasters or health crises, and the result is unprecedented supply chain fragility.

Companies now face potential disruptions at every node: supplier instability, manufacturing delays, transportation bottlenecks, port congestion, labor shortages, and sudden demand surges or collapses. The ripple effects of a single localized event can cascade globally, impacting inventory levels, production schedules, delivery times, customer satisfaction, and ultimately, the bottom line. Relying solely on historical data or static plans is like navigating a minefield with an outdated map. Businesses need the foresight to anticipate potential futures and the agility to adapt – they need adaptive supply chains built on a foundation of resilience.

Understanding Dynamic Scenario Simulation (DSS): More Than Just Planning

So, what exactly is Dynamic Scenario Simulation? Think of it as a sophisticated "flight simulator" for your entire supply chain. It's a technology-driven approach that creates a virtual, dynamic model – a Digital Twin – of your end-to-end operations. Leveraging machine learning (ML) for predictive analysis, and advanced deterministic simulation, DSS allows users to simulate a multitude of potential disruptive events and analyse their cascading impacts in real-time.

Leading approaches, such as Simcel's Dynamic Scenario Simulation (DSS) technology developed over twelve years of R&D and real-world experiments, move far beyond static snapshots. They uniquely combine foundations like System Dynamics (modeling flows and stocks across the network over time) with Discrete Event Logic (governing behavior through explicit business rules and triggers), executed deterministically for traceable results while incorporating probabilistic inputs like ML-driven demand prediction. This contrasts sharply with traditional planning tools relying on static inputs, often averaged, simulation methods - which end ups being closer to an Excel spreadsheet than an proper simulation. Such dynamic simulation creates a fundamental shift in how supply chains can be modeled, analyzed, and optimized. Unlike static models, advanced DSS captures:

Interconnectedness: It understands how a disruption in one area (e.g., a supplier shutdown) affects others (manufacturing, logistics, inventory).

Feedback Loops: It accounts for how decisions or events can create secondary and tertiary effects that loop back into the system.

Non-Linear Relationships: It captures the complex, often unpredictable ways different variables interact within the supply chain ecosystem.

Real-Time Data Integration: It can incorporate live feeds (market data, geopolitical alerts, weather patterns, IoT sensor data) for more accurate and timely simulations.

DSS moves beyond simple forecasting to explore the plausibility and impact of various futures without loosing the ability to understand the root cause of specific effect (as opposed to machine learning models that create a black box effect).

Objectives, Mechanics, and Transformative Benefits of DSS

The core objective of DSS is to shift businesses from a reactive posture to one of proactive preparedness. It's about empowering decision-makers to anticipate disruptions, understand their potential consequences, and formulate mitigation strategies before disaster strikes. The objective is to inject Agility and data-driven foresight into core planning processes like Sales & Operations Planning (S&OP) and Integrated Business Planning (IBP). This recognizes that plans should evolve as new insights emerge about previously unforeseen circumstances.

How it Works (The DSS Cycle):

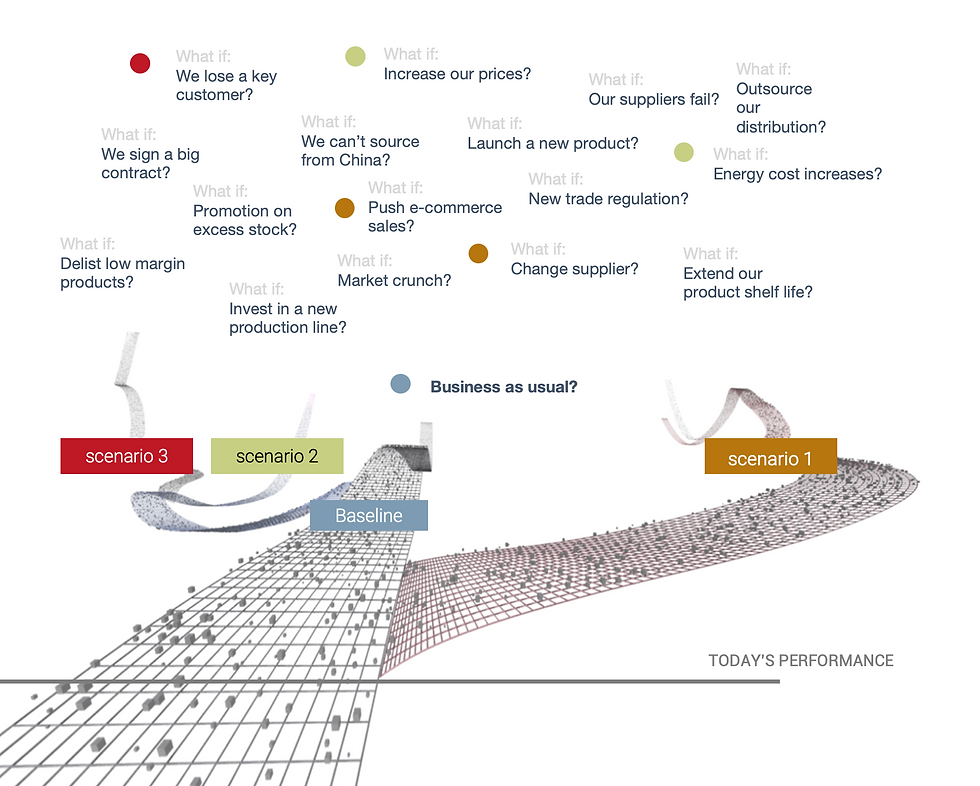

Establish Baseline & Drivers: Create the baseline with the Digital Twin by simulating the most probable "business as usual" scenario using the baseline forecast and existing supply chain levels, structures and rules.

Define Scenarios: Develop plausible "what-if" scenarios, including externally driven events (macro-environmental shifts, tariff changes, port congestions, supplier failures) and decision-driven events (new market entries, product launches, promotional campaigns, pricing adjustments, supplier changes, maintenance periods) – as well as composing scenarios combining these events together

Simulate & Analyze Impact: Run scenarios through the Digital Twin simulation engine. This engine processes scenarios with high fidelity, modeling detailed time-resolved operations day-by-day and realistically accounting for capacity constraints across sourcing, production, transport, and storage. It rapidly calculates impacts on KPIs like cost-to-serve, revenue projections, inventory, service level, and resource utilization and ultimately profit (EBIT level) and carbon emissions.

Compare & Decide: Evaluate outcomes of different scenarios against strategic and financial targets and assess business-level trade-offs such as Growth vs. Profit, Revenue vs. Working Capital, Customer Service vs. Profit, etc.

Optimize & Act: Refine the optimal plan based on simulation insights, implement chosen strategies, monitor execution and planning adherence and adjust plans on the go as new events emerge.

Key Benefits:

Improved Risk Mitigation: Identify vulnerabilities and quantify potential impacts proactively.

Enhanced Decision-Making: Faster, more confident choices based on data-driven insights.

Increased Supply Chain Agility: Rapidly test responses and adapt to changes.

Greater Resilience & Business Continuity: Develop robust, simulation-validated contingency plans.

Enhanced Cross-Functional Alignment: Provides a common view for better collaboration across Sales, Operations, Finance, and Supply Chain during S&OP/IBP cycles.

Precision Over Approximation: Replaces broad averages with dynamic, granular insights into operations and costs.

Traceability and Transparency: Ensures every outcome can be clearly traced back to specific inputs, assumptions, and deterministic business rules.

Optimized Strategies & Reduced Costs: Find cost-effective ways to build resilience and manage operations.

Competitive Advantage: Gain market share and trust through superior navigation of disruptions.

Clear ROI: Demonstrate tangible returns through avoided costs and improved efficiency and clearly measurable benefits on the bottom line.

Taming Global Complexity: DSS in the Geopolitical Arena

For businesses with global operations, DSS is particularly powerful. It enables modelling the impact of specific, concrete events, whether it's a sudden tariff implementation, a key supplier shutdown, a transportation delay, or a planned promotional campaign. DSS enables decision makers to:

Model Geopolitical Impacts: Simulate the effects of trade wars, sanctions, export controls, or political instability on sourcing strategies, supplier viability, and distribution networks across different countries and regions.

Assess Economic Volatility: Simulate the impact of currency fluctuations, inflation spikes, or regional economic downturns on landed costs, profitability, and demand patterns.

Optimize Complex Logistics: Analyze and stress-test multi-modal, cross-border logistics networks, identifying bottlenecks and optimizing routes considering potential disruptions.

Enhance Partner Collaboration: Share simulation insights with key suppliers and logistics partners to align on contingency plans.

Evaluate Strategic Opportunities: Beyond mitigating risks, DSS also allows decision makers to simulate the potential upside of strategic opportunities in different markets, testing expansion scenarios under various economic conditions.

DSS provides the tools to quantify both risks and opportunities associated with global uncertainty, enabling informed strategic decisions.

Navigating Implementation: Considerations and Constraints

While the benefits are compelling, implementing DSS requires careful planning:

Data Quality and Availability: Accurate, comprehensive, and timely data is the foundation. Data cleansing and integration efforts are crucial. This comes with the data integration layers that gather, review, clean transform data originally coming for the various information systems - essentially from the ERP

Model Complexity vs. Feasibility: Finding the right balance between model detail and practical constraints is crucial. Initial scoping ensures that simulations can address key decisions without becoming overwhelmingly complex or resource-intensive.

Change Management: Effective training, clear communication, and fostering user adoption across relevant teams are essential to realizing its full potential. It involves cross functional deployment to avoid being “just an other supply chain tool” but a truly cross functional collaboration IBP platform

Initial Investment: Implementing sophisticated DSS platforms involves upfront costs. However, this should be viewed against the significant potential ROI. Partnering with the right provider can streamline this process.

These are manageable factors, often addressed effectively with experienced solution providers.

Empowering Strategic Leadership: Value for CFOs and Supply Chain Leaders

Dynamic Scenario Simulation delivers profound strategic value, particularly for Chief Financial Officers (CFOs) and Supply Chain Leaders, fostering alignment between operational resilience and financial stewardship. For Supply Chain Leaders, DSS provides strategic foresight for robust cost efficiency, demand fulfilment performance and risk management. For CFOs, it translates operational scenarios into clear financial terms, enabling quantification of financial exposure and informed decisions on revenue, profitability and working capital at macro (company level P&L) and micro level (customer-product P&L).

Furthermore, advanced DSS platforms like Simcel's provide Dynamic Cost Allocation also referred to as Activity-Based-Costing. Unlike traditional systems using static averages, this capability models asset utilization (warehouses, lines, vehicles) in real-time during simulation, allocating fixed costs based on actual throughput. This reveals the true cost-to-serve per product and customer under different conditions (e.g., peak vs. low volume), uncovering hidden profitability insights crucial for accurate financial analysis on product portfolio, pricing or distribution decisions – insights obscured by static cost models.

Crucially, DSS provides a common ground, enabling C-levels to collaboratively assess ROI, understand the cost of inaction, and make unified decisions that are consistent from end-to-end. It transforms the conversation across the leadership team, aligning strategic planning with quantifiable risk and financial outcomes.

The Future is Predictive: Evolving Capabilities

While ML models may progressively predict distruptive events more accurately, most organisations fail in using such stand alone predictions in their decision making processes. Digital Twin connects various events together and translate them into business impact. Advancements in AI make simulations smarter by providing probabilistic inputs to deterministic scenario simulation.

In this context, the core Digital Twin market, foundational to advanced simulation, is projected to grow over 30% annually (McKinsey), underscoring this momentum.

This evolution paves the way for more autonomous supply chain management. The detailed simulations generated by DSS serve as ideal digital experimentation platforms and data simulated (synthetic data) can be used as training grounds for AI agents, enabling the development of intelligent, automated response systems. Leading platforms support event-driven automation where systems adjust plans based on emerging conditions, fostering a continuous learning loop for self-improving supply chains and providing executives with quantified decision support intelligence.

Simcel: Your Partner for an Adaptive, AI-Powered Supply Chain

Navigating complexity and harnessing DSS requires the right technology and expertise. This is where Simcel excels, leveraging twelve years of R&D to pioneer its proprietary Dynamic Scenario Simulation (DSS) approach, uniquely combining System Dynamics, Discrete Event Logic, deterministic execution, and probabilistic inputs.

Our AI-powered platform, built on a dynamic Digital Twin, enables powerful Scenario Planning and What-if Analysis. It’s built for enterprise scale, capable of simulating a full year of complex operations (handling thousands of customers, hundreds of products, multiple facilities) in under one minute, leveraging parallel processing for maximum speed. We provide precision over approximation, full traceability, and the rapid response capability needed to identify risks, optimize resources, and thrive amidst uncertainty. Simcel supports advanced operational research and the journey towards more autonomous decision-making.

Choosing Simcel means choosing a partner dedicated to transforming your supply chain with advanced technology and deep domain expertise to achieve tangible ROI.

Conclusion: From Vulnerable to Adaptive

In an era defined by volatility, hoping for the best isn't a strategy. Dynamic Scenario Simulation offers a path forward, transforming supply chains into resilient, adaptive engines of growth. By harnessing Digital Twins, AI, and proactive "what-if" analysis, businesses can anticipate challenges, make smarter decisions faster, and protect their operations against the storms of uncertainty. Adopting DSS is no longer a luxury; it is a strategic imperative.

Ready to transform your supply chain from vulnerable to adaptive?

The most direct way to understand how Simcel's AI-powered platform can elevate your planning. Let’s discuss today:

Quality sharing - not much content on this topic online, makes it pretty clear😍

Great learnings👍